Team Name: Computational Mechanics Theory and Applications Research Group

Brief Introduction:

The team focused on major education and research center inBasic Research on Mechanics of New Materials in China. It provides undergraduate to post graduate education incomputational mechanicsmore than50students received their Master or Doctoral degrees in the last 5 years. The research activities in the Computational Mechanics Theory and Applications Research Group includes key research fields as follows:

Theoretical foundations and applications of computational mechanics

Meshless methods for impact dynamics, fluid mechanics, and fluid-structure interaction

Special protective structure design and analysis

The deformation behaviors and mechanisms of ceramics

Crystal plasticity theory and multiscale simulation

Research on micro-nano mechanical behaviors

Computational fluid dynamics and high-speed aerodynamics

Fluid-structure interaction dynamics and control

Nuclear material corrosion and degradation

The Computational Mechanics Theory and Applications Research Group at WHUT has been working on education of computational mechanicssince 2001. The team was composed of 3professor and 6vice professors.And the team faculty members are listed as:

|

|

|

Lisheng Liu | Xin Lai | Jun Li |

|

|

|

Hai Mei | Liangliang Chu | Shuang Xu |

|

|

|

Maoyuan Jiang | Yazhong Jiang | Lin Ren |

|

|

|

Zhen Wang | Xiang Liu | Tianli Jiang |

| ||

Zhikun Zhou |

Lab Resource

Labs:

Lab 1 Additive Manufacturing Laboratory

Position:Mechanics building, office 402

Email:liuxiang1129@whut.edu.cn

Working hour:8:00 am ~17:00 pm, Monday~Friday

Lab 2 Super computer Laboratory

Position:Mechanics building, office 504

Email:laixin@whut.edu.cn

Working hour:8:00 am ~17:00 pm, Monday~Friday

Instrumentation &Facilities:

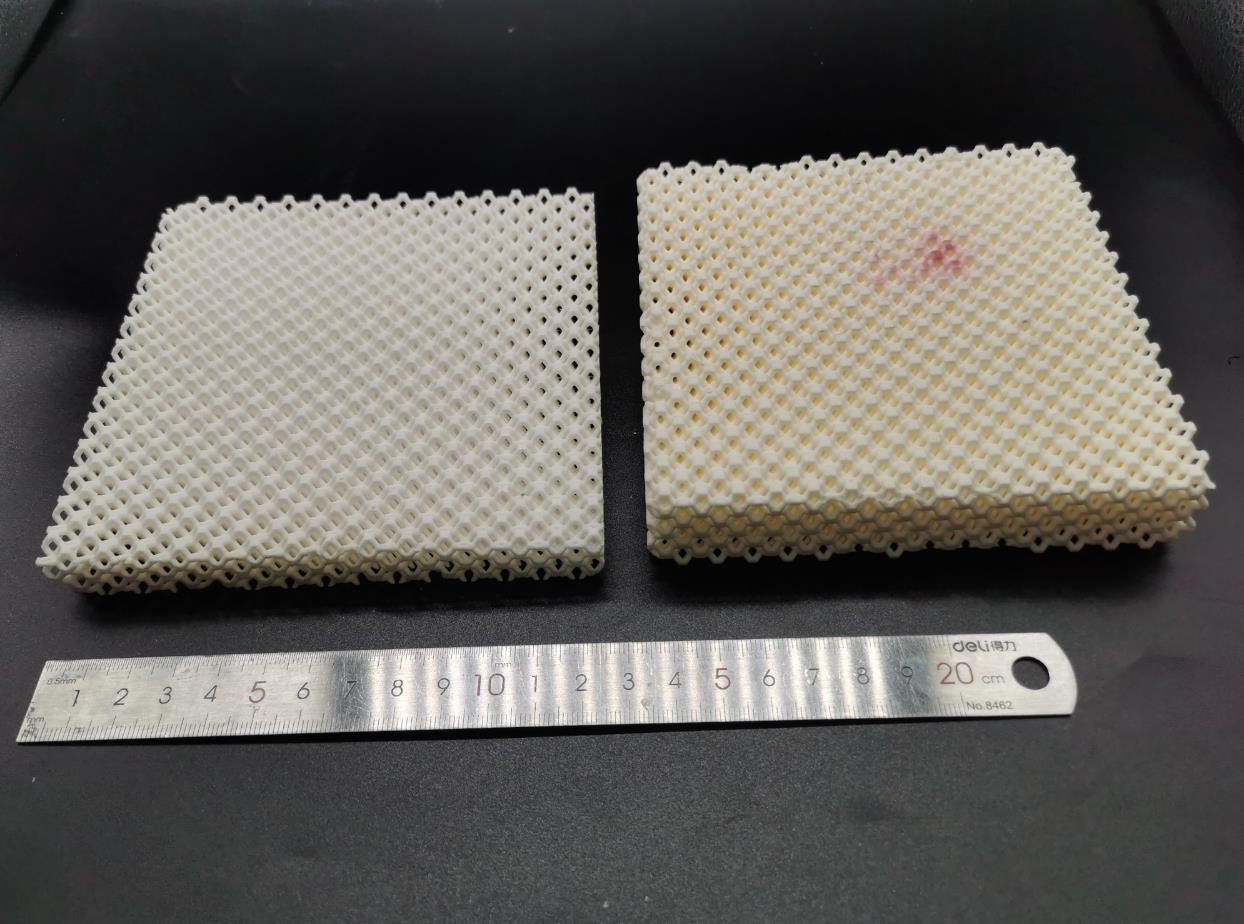

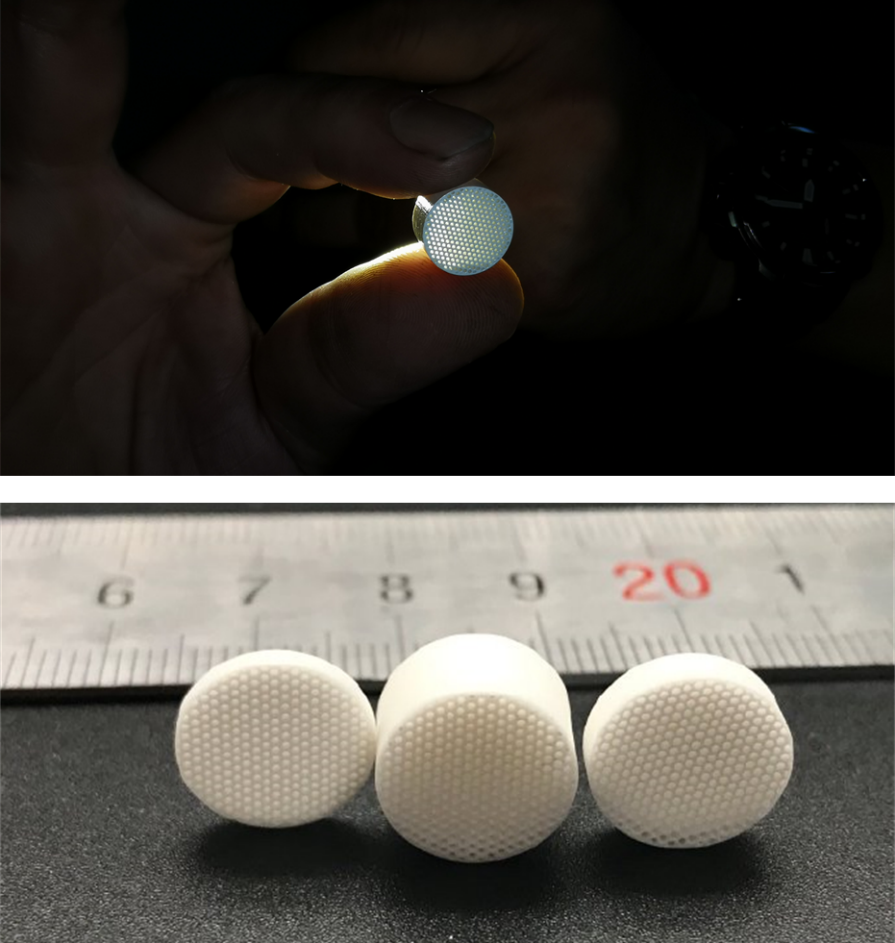

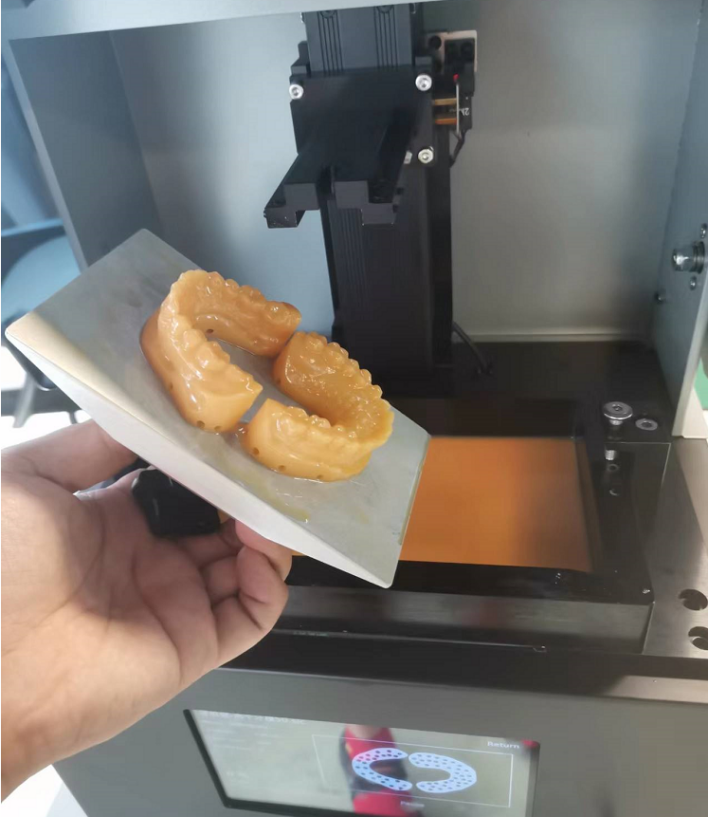

CeraBuilder 100pro

Lab:Additive Manufacturing Laboratory

Function:Advanced ceramic structure manufacturing

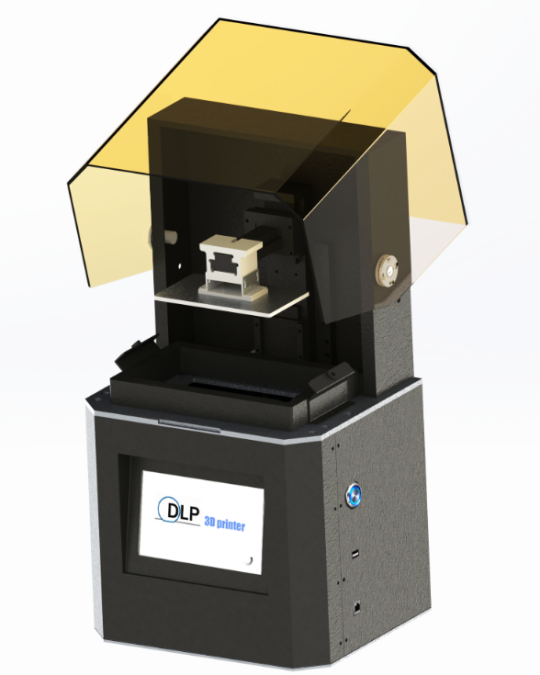

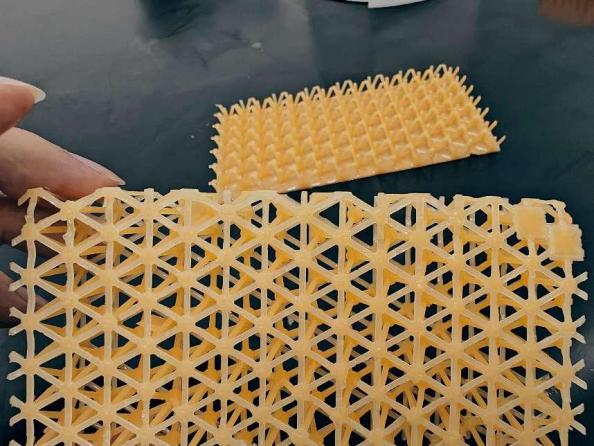

DLP 3d printer Prism S3

Lab:Additive Manufacturing Laboratory

Function:Advanced photosensitive-resin structure manufacturing

High-performance blade computer cluster

Lab:Super computer Laboratory

Function:High-performance parallel computing

Team achievements

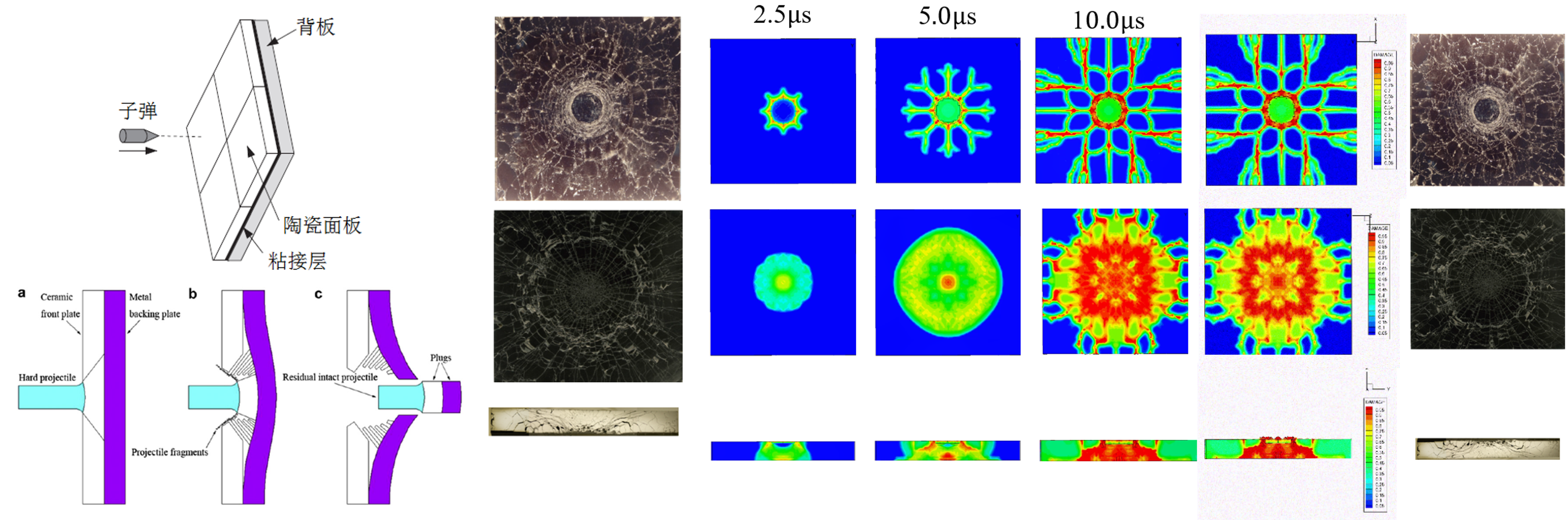

Research Area 1: Peridynamics simulation and experimental study on anti-penetration performance of ceramic composite armor

Liu Y, Liu L, Mei H*, et al. A modified rate-dependent peridynamic model with rotation effect for dynamic mechanical behavior of ceramic materials[J]. Computer Methods in Applied Mechanics and Engineering, 2022, 388:114246.

Wang D, Mei H*, Liu L, et al. The effect of heating rate on sintering mechanism of alumina nanoparticles[J]. Journal of the American Ceramic Society, 2022, 105(12): 7149-7158

Dangqiang Wang, Jian Hu, Jun Li, Hai Mei*. In situ synthesis of Si3N4/h-BN composites by hot-pressed sintering[J]. Ceramics International, 2025, Vol. 51(5): 6793-6798.

Li Y, Liu Q, Liu L. The Coupled Thermo-Chemo-Mechanical Peridynamics for ZrB2 Ceramics Ablation Behavior[J]. Computer Modeling in Engineering and Sciences, 135(1): 417-439 (2023).

Li, S., Lai, X. and Liu, L. Peridynamic Modeling of Brittle Fracture in Mindlin-Reissner Shell Theory. Computer Modeling in Engineering & Sciences, 715-746, 131 (2022).

Lai, X. et al. A non-ordinary state-based peridynamics modeling of fractures in quasi-brittle materials, International Journal of Impact Engineering, 2018, 111: 130-146.

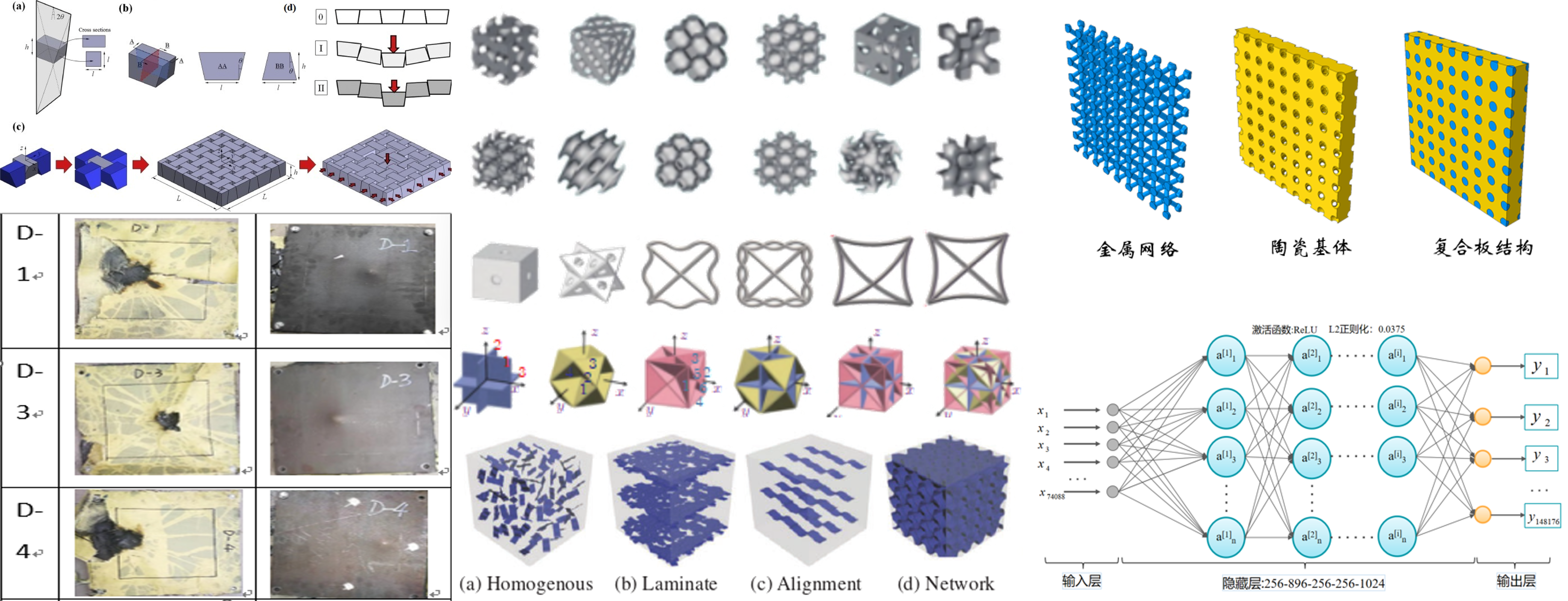

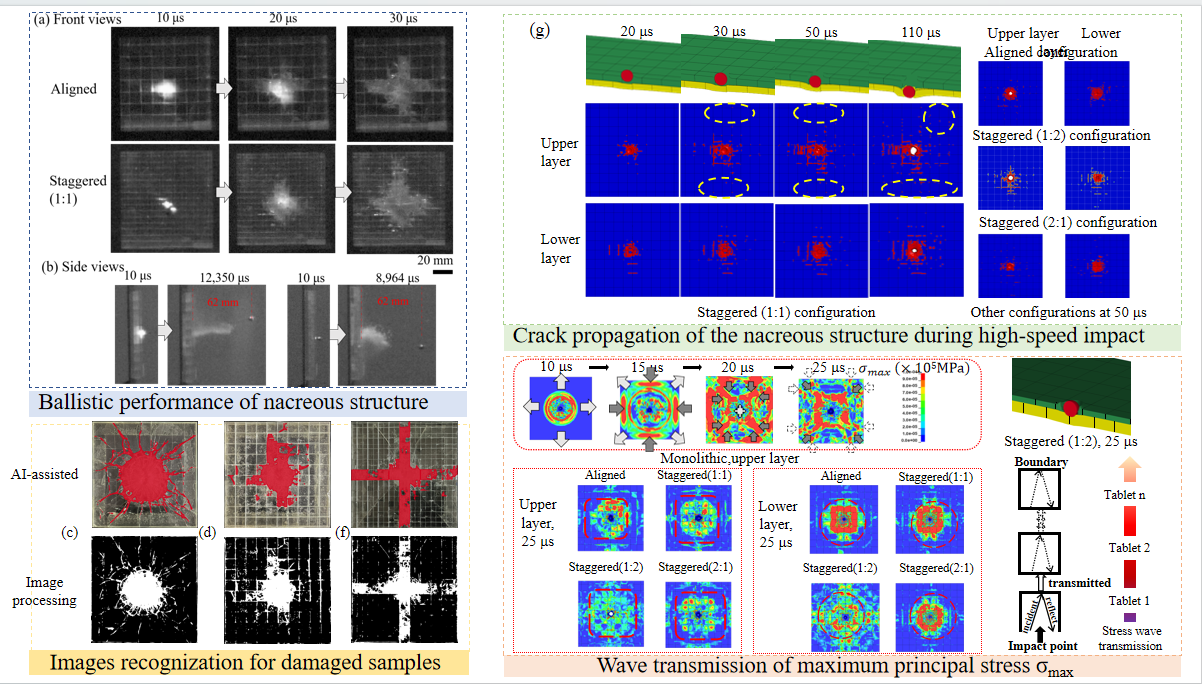

Research Area 2: Design and analysis of special protective structures

Jun Sun, Chunxu Zhao, Jun Li, Hai Mei, Xiang Liu, Shilin Yan, Biomimetic nacreous structure enhances the impact resistance of transparent protective composites, Materials & Design, 2025,258(10),114679.

Zhang, X., Liu, Y., Mei, H., Liu, L., Zhang, J., Lai, X., Li, J., 2024. The high-impact resistance bionic transparent composite material with octahedral structure. Meccanica 59, 939–959.

Liu, K., Lai, X., Liu, L., Zhang, J., Liu, Y., 2025. Optimal design approach of interpenetrating pre-stressed metal-ceramic composites based on deep learning neural network. Composite Structures 368, 119275.

Yuan, H., Li, J., Mei, H., Lai, X., Liu, X., Liu, L., 2024. Bioinspired transparent hexahedral structural design enables high-impact resistance composites. Acta Mech 235, 2959–2977.

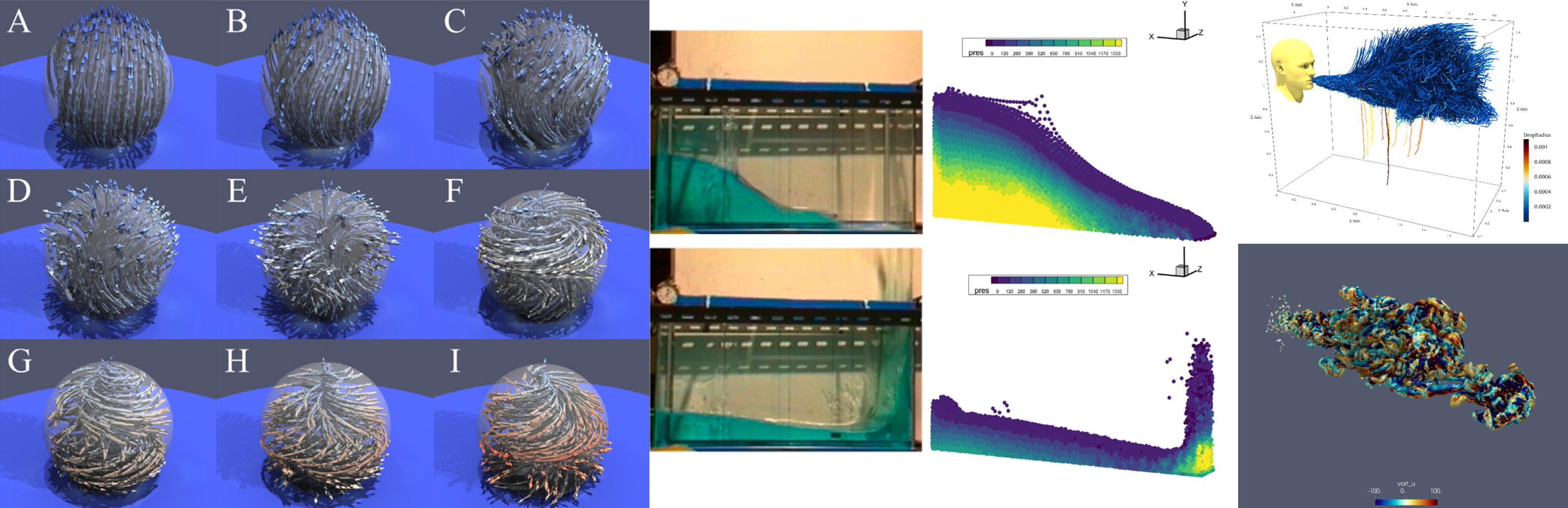

Research Area 3: Meshless methods and finite element methods for fluid mechanics and fluid-structure interaction

|

|

|

|

|

|

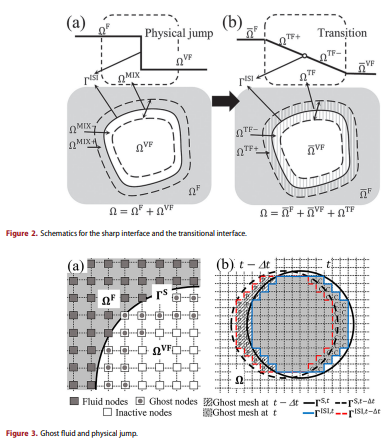

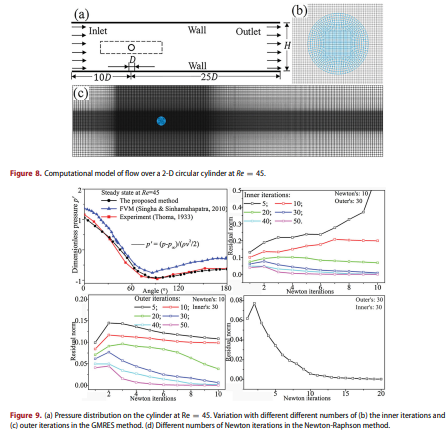

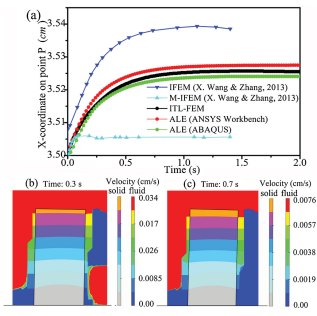

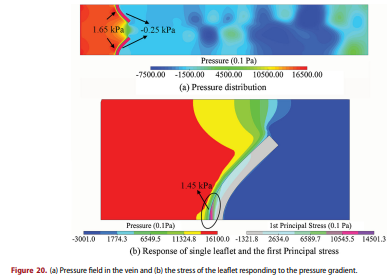

Liu, X.; Liu, L.*; An immersed transitional interface finite element method for fluid interacting with rigid/deformable solid, Engineering Applications of Computational Fluid Mechanics, 2019, 13(1): 337-358.

Lai, X., Li, S., Yan, J., Liu, L., Zhang, A.-M., 2022. Multiphase large-eddy simulations of human cough jet development and expiratory droplet dispersion. J. Fluid Mech. 942, A12.

Wang, A., Lai, X., Yan, J., Liu, L., 2025. Graphics processing unit-accelerated updated Lagrangian particle hydrodynamics modeling of heat conduction and convection problems. Physics of Fluids 37.

Wang, Z., Xiong, J., Li, S., Lai, X., Liu, X., Liu, L., 2024. An Updated Lagrangian Particle Hydrodynamics (ULPH)-NOSBPD CouplingApproachfor Modeling Fluid-Structure Interaction Problem. CMES 141, 491–523.

Xiong, J., Wang, Z., Li, S., Lai, X., Liu, L., Liu, X., 2025. An updated Lagrangian particle hydrodynamics (ULPH) implementation of heat conduction model for weakly-compressive fluid. Comp. Part. Mech. 12, 1249–1261.

Xiong, J., Wang, Z., Li, S., Lai, X., Liu, L., Liu, X., 2024. Updated Lagrangian Particle Hydrodynamics (ULPH) Modeling of Natural Convection Problems. CMES 141, 151–169.

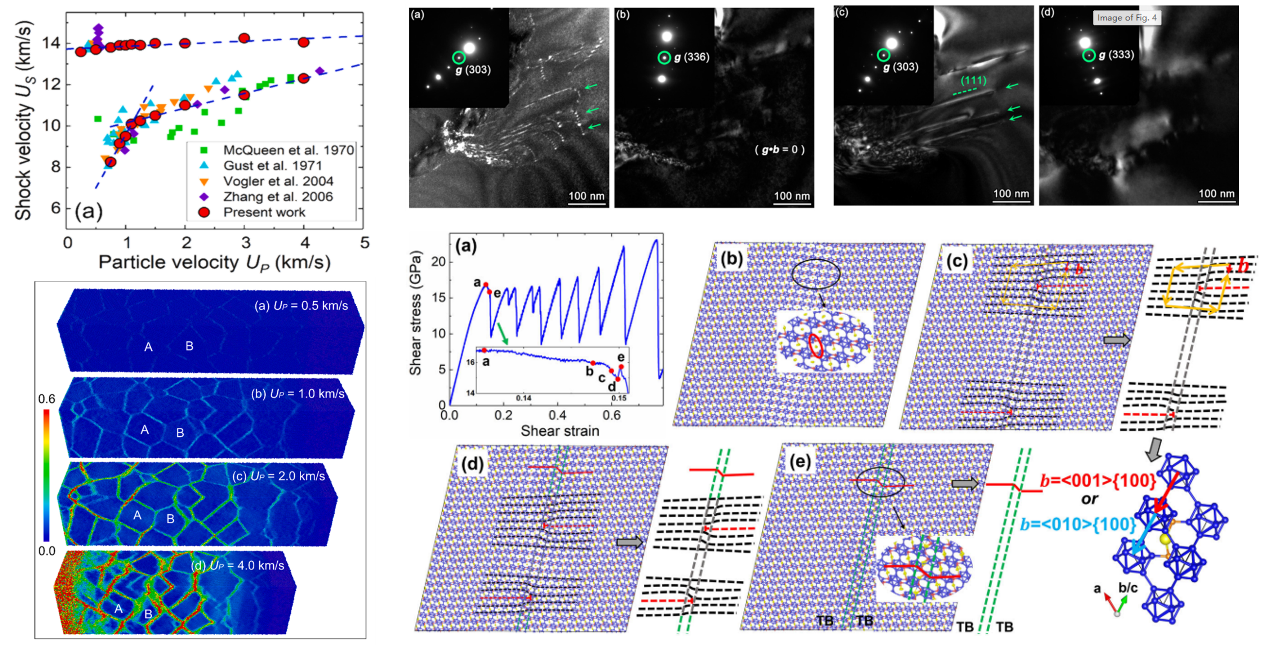

Research Area 4: The deformation behaviors and mechanisms of ceramics

Jun Li, K Luo, Q An. Activating mobile dislocation in boron carbide at room temperature via Al doping, Physical Review Letters, 2023, 130: 116104.

P Li#,Jun Li#, Q Feng#, T Jin, et al. Unveiling high ductility in boron carbide crystal at room temperature, Science Advances, 2025, 11, eadr4648.

Jun Li, K Luo, Q An, Atomic structure, stability, and dissociation of dislocations in cadmium telluride, International Journal of Plasticity, 2023, 163: 103552.

Jun Li, K Luo, Q An. Unraveling the Hall-Petch to inverse Hall-Petch transition in nanocrystalline CdTe, International Journal of Mechanical Sciences, 2025, 286, 109852.

Jun Li, K Luo, Q An. Temperature-dependent competition between dislocation motion and phase transition in CdTe, Journal of Materials Science & Technology, 2025, 226, 109-121.

M Li#,Jun Li#, K Luo#, S Yang, Tobin F, Q An, Y Zou. Opposite effects of doping on nanoindentation pop-in phenomena in InAs and Ge crystals, Scripta Materialia, 2025, 261, 116607. (共同一作)

Jun Li, K Luo, Q An. Mobile dislocation mediated Hall-Petch and inverse Hall-Petch behaviors in nanocrystalline Al-doped boron carbide [J].Journal of the European Ceramic Society, 2024, 44(2): 659-667.

Jun Li, K Luo, Q An.Elucidating twinning mechanisms in cdte homoepitaxial film growth from machine learning force field molecular dynamics simulations [J]. Crystal Growth & Design, 2024, 24: 7484-7493.

Jun Li, Q An. Nanotwinning-induced Pseudoplastic Deformation in Boron Carbide under Low Temperature [J]. International Journal of Mechanical Sciences, 2023, 242, 107998.

Jun Li, Q An. Quasiplastic Deformation in Shocked Nanocrystalline Boron Carbide: Grain Boundary Sliding and Local Amorphization [J]. Journal of the European Ceramic Society, 2023, 43(2): 208-216.

Jun Li, Q An. Shear-induced Amorphization in Boron Subphosphide (B12P2): Direct Transition versus Stacking Fault Mediation [J]. Journal of the American Ceramic Society, 2022, 105(11): 6826-6838.

Jun Li, S Li, X Lai, L Liu. Peridynamic Stress is the Static First Piola–Kirchhoff Virial Stress [J]. International Journal of Solids and Structures, 2022, 241: 111478.

Jun Li, Q An, L Liu. Local Amorphization in Boron Carbide at Finite Temperature: Strategies toward Improved Ductility [J]. Physical Review B, 2021, 104: 134105.

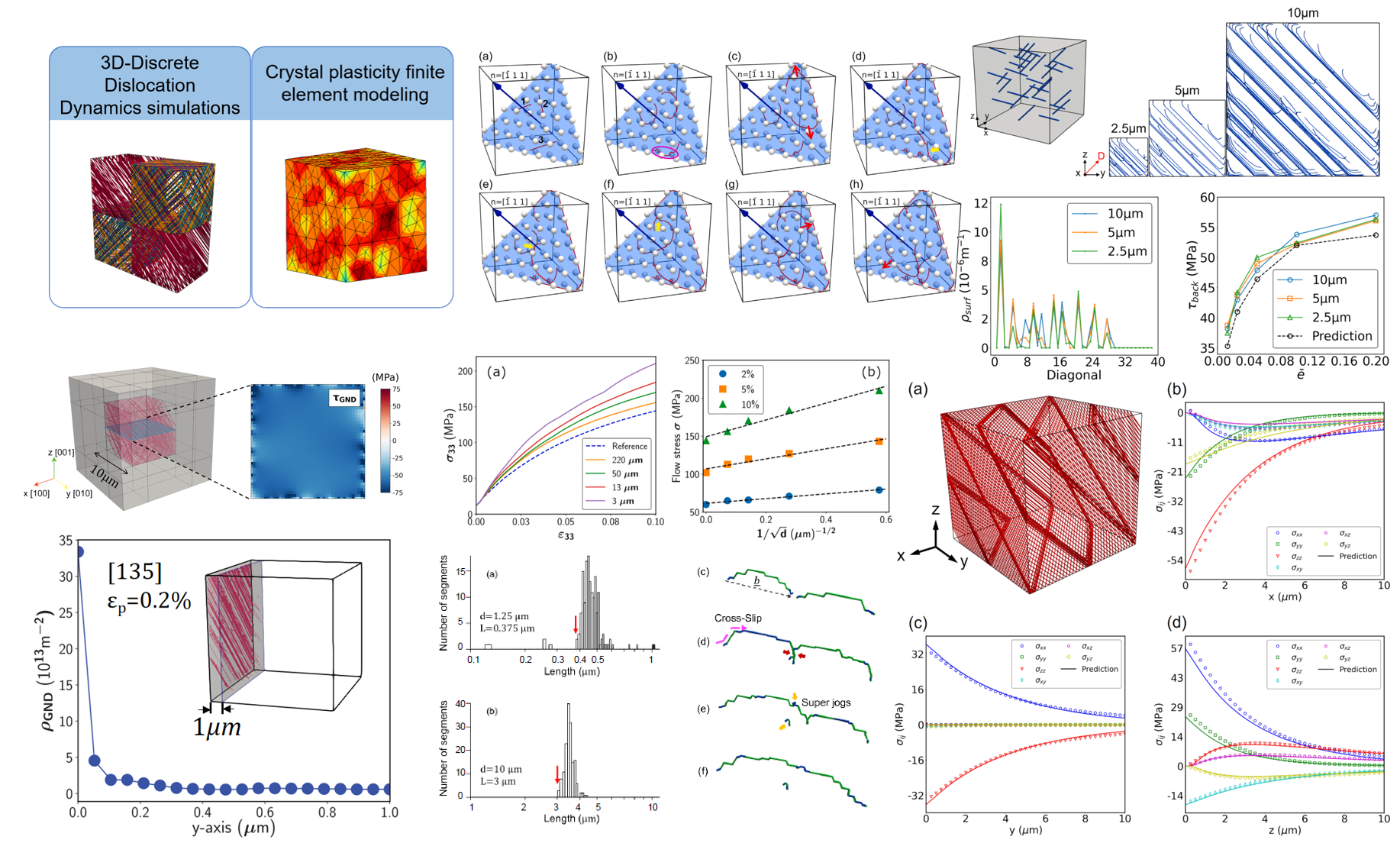

Research Area 5: Crystal plasticity theory and multiscale simulations

Tao Zhang, Shuang Xu, Lisheng Liu, Maoyuan Jiang*, Long-range internal stress from non-uniform geometri-

cally necessary dislocations: A prediction method refined by dislocation dynamics simulations, International Journal of Plasticity, 2025, 188, 104316

[2] Tao Zhang, Shuang Xu, Xin Lai, Lisheng Liu, Maoyuan Jiang*, A mesoscale numerical study on the geometrically necessary dislocations at grain boundaries and the back stress in polycrystalline grains, Acta Mechanica Sinica, 2025, accepted

[3] Maoyuan Jiang*, Xuzhi Zhang, Hai Mei, Shuang Xu, Lisheng Liu, The coupled effects of grain boundary strengthening and Orowan strengthening examined by dislocation dynamics simulations, Computational Materials Science, 2024, 231, 112602

[4] Maoyuan Jiang*, Zhengxuan Fan, Serge Kruch, Benoit Devincre*, Grain size effect of FCC polycrystal: A new CPFEM approach based on surface geometrically necessary dislocations, International Journal of Plasticity, 2022, 150, 103181

[5] Maoyuan Jiang*, Benoit Devincre, Uncovering the existence of anti-backstress associated with dislocations accumulated at grain boundaries during plastic deformation, Computational Materials Science, 2022, 208, 111328

[6] Maoyuan Jiang*, Ghiath Monnet, Benoit Devincre, On the origin of the Hall-Petch law: a 3D-Dislocation Dynamics simulation investigation, Acta Materialia, 2021, 209, 116783

[7] Maoyuan Jiang, Ghiath Monnet, Benoit Devincre*, Stress fields of finite-size dislocation walls and prediction of back stress induced by geometrically necessary dislocations at grain boundaries, Journal of the Mechanics and Physics of Solids, 2020, 143, 104071

[8] Maoyuan Jiang, Benoit Devincre, Ghiath Monnet*. Effects of the grain size and shape on the flow stress: a dislocation dynamics study, International Journal of Plasticity, 2019, 113, 111-124

Research Area 6: Computational fluid dynamics and high-speed aerodynamics

Jiang Yazhong, Shi Lisong*, Wen Chih-Yung. Analysis and applications of the upwind conservation element and solution element scheme for compressible flow simulations. Physics of Fluids, 2024, 36: 126150

Jiang Yazhong, Wen Chih-Yung*. On the conservative property of particle-based Fokker–Planck method for rarefied gas flows. Physics of Fluids, 2020, 32: 127108

Liang Yu, Jiang Yazhong*, Wen Chih-Yung, Liu Yao. Interaction of a planar shock wave and a water droplet embedded with a vapour cavity. Journal of Fluid Mechanics, 2020, 885: R6

Sun Xuxu, Liu Weikang, Jiang Yazhong*, Li Guochun, Kong Desi, Yao Jiaxin, Chen Xianfeng. Effects of the single orifice plate on the failure and re-initiation of quasi-detonation in stoichiometric hydrogen–oxygen mixtures. Fuel, 2026, 405: 136617.

Jiang Yazhong*, Ling Yuxing, Zhang Shikang. Investigation of the inverse magnus effect on a rotating sphere in hypersonic rarefied flow. Applied Sciences, 2024, 14: 1042

Jiang Yazhong, Wen Chih-Yung*, Zhang Deliang. Space–time conservation element and solution element method and its applications. AIAA Journal, 2020, 58(12): 5408−5430

Jiang Yazhong, Gao Zhenxun*, Lee Chun-Hian. Particle simulation of nonequilibrium gas flows based on ellipsoidal statistical Fokker-Planck model.Computers and Fluids, 2018, 170: 106−120

Jiang Yazhong, Gao Zhenxun*, Jiang Chongwen, Lee Chun-Hian. Hypersonic aeroheating characteristics of leading edges with different nose radii. Journal of Thermophysics and Heat Transfer, 2017, 31(3): 538−548

Wen Chih-Yung, Jiang Yazhong, Shi Lisong. Space–Time Conservation Element and Solution Element Method. Springer, 2023

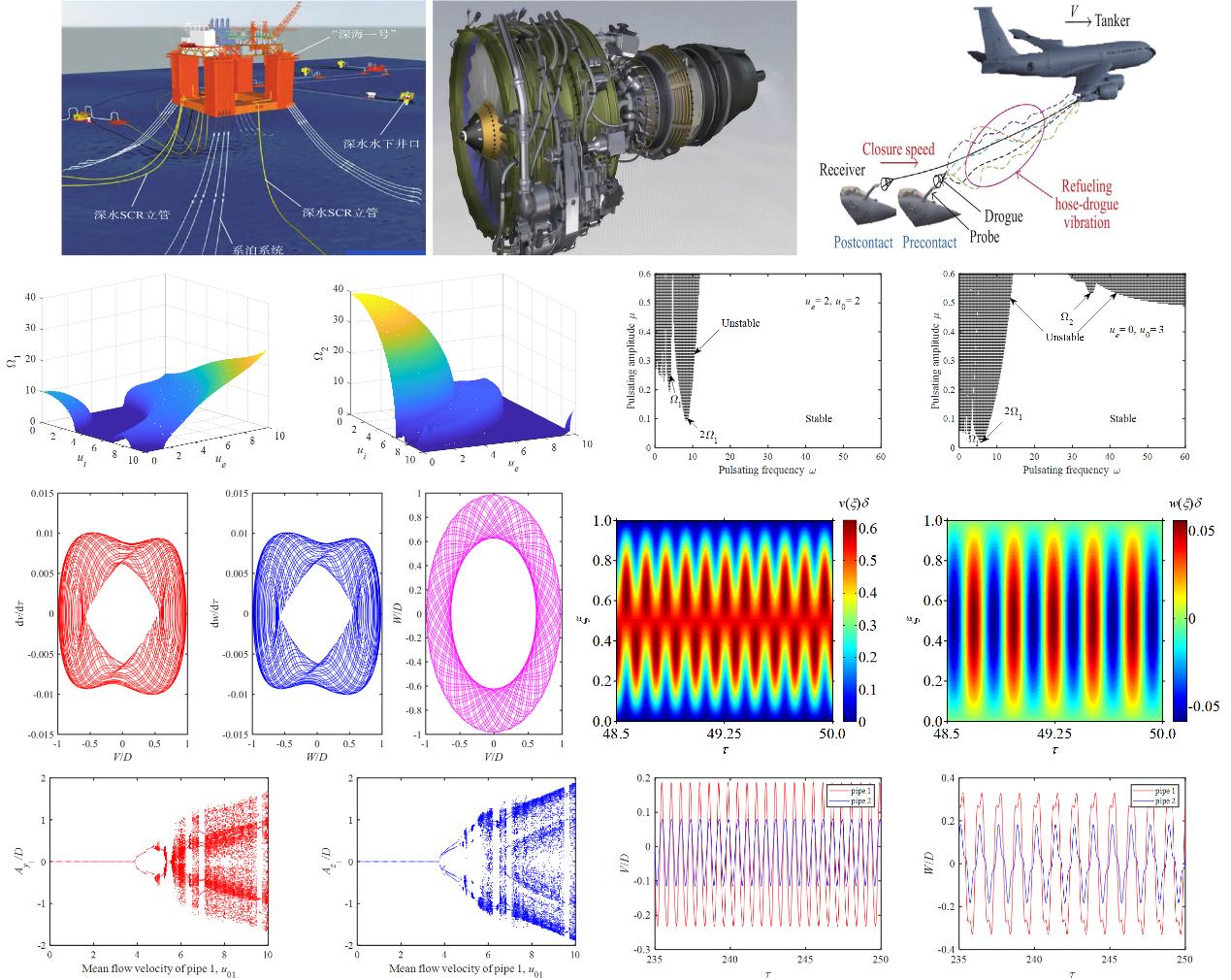

Research Area 7: Fluid-Structure Interaction Dynamics and Control

Wang Dali, Jiang Tianli*, Dai Huliang, Wang Lin. Non-planar vibration characteristics and buckling behaviors of two fluid-conveying pipes coupled with an intermediate spring[J]. Applied Mathematics and Mechanics (English Edition), 2025, 46(10): 1829-1850.

Jiang Tianli, Dai Huliang, Wang Lin*. Three-dimensional dynamics of fluid-conveying pipe simultaneously subjected to external axial flow[J]. Ocean Engineering, 2020, 217: 107970.

Jiang Tianli, Dai Huliang, Wang Lin*. Three-dimensional dynamics and synchronization of two coupled fluid-conveying pipes with intermediate springs[J]. Communications in Nonlinear Science and Numerical Simulation, 2022, 115: 106777.

Jiang Tianli, Dai Huliang, Zhou Kun, Wang Lin*. Nonplanar post-buckling analysis of simply supported pipes conveying fluid with an axially sliding downstream end[J]. Applied Mathematics and Mechanics (English Edition), 2020, 41(1): 15-32.

Jiang Tianli, Liu Zhiyuan, Dai Huliang, Wang Lin*, He Fang*. Nonplanar multi-modal vibrations of fluid-conveying risers under shear cross flows[J]. Applied Ocean Research, 2019, 88: 187-209.

Wang Lin, Jiang Tianli, Dai Huliang*, Ni Qiao. Three-dimensional vortex-induced vibrations of supported pipes conveying fluid based on wake oscillator models[J]. Journal of Sound and Vibration, 2018, 422: 590-612.

Wang Lin, Jiang Tianli, Dai Huliang*. Three-dimensional dynamics of supported pipes conveying fluid[J]. Acta Mechanica Sinica, 2017, 33(6): 1065-1074.

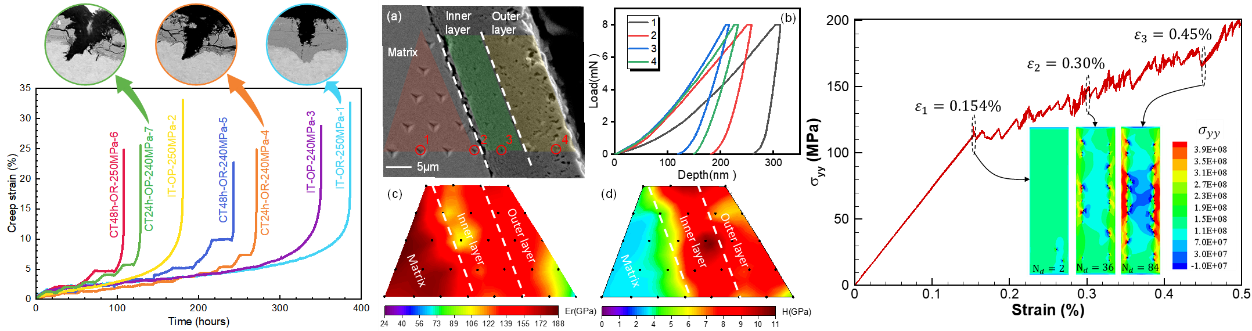

Research Area 8: Nuclear material corrosion and degradation

Du, J., Zhou, Z., Luo, K., Zhang, Q., Liu, L., Chen, Z., & Gong, X. (2025). Liquid metal embrittlement of T91 steel in liquid lead–bismuth eutectic: The role of long-term pre-exposure and threshold stress of crack initiation. Engineering Fracture Mechanics, 330, 111644.

Tian, C., Zhou, Z., Du, J., Fan, S., & Chen, Z. (2025). A peridynamic model for oxidation of T91 steel in liquid lead-bismuth eutectic. Journal of Nuclear Materials, 605, 155594.

Zhou, Z., Tian, C., Zhang, Q., Du, J., Zhang, C., Liu, H., Gong, X., Abdel Wahab, M., & Chen, Z. (2024). Creep-to-rupture of T91 steel in static liquid lead-bismuth eutectic: Effects of cyclic temperature and oxygen environment. Engineering Fracture Mechanics, 311, 110539.

Zhou, Z., Tian, C., Du, J., Peng, X., Liu, Y., Yu, X., Mi, X., Pu, Z., Xie, H., Abdel Wahab, M., & Chen, Z. (2024). New insights into oxidation mechanism and kinetics of 9Cr-1Mo ferritic-martensitic steel in oxygen-saturated liquid lead-bismuth eutectic. Journal of Alloys and Compounds, 997, 174825.

Zhou, Z., Tian, C., Dong, W., Du, J., Liu, Y., Abdel Wahab, M., & Chen, Z. (2024). Enhanced toughness and ductility of T91 steel after exposure to liquid LBE saturated by oxygen at 350-500 °C. Journal of Materials Research and Technology, 30, 5455-5464.

Zhou, Z., Du, J., Tian, C., Peng, X., Wu, Y., Lv, X., Zhang, Y., & Chen, Z. (2024). Local mechanical properties of corrosion layers formed on T91 and SS316L steels after exposure to static liquid LBE at 500 °C for 1000 h obtained by nano-indentation. Nuclear Engineering and Technology, 56, 3067–3075.